3D Print Service

We offer access to advanced 3D printing technologies and high-quality materials. This means customers can count on high-quality prints with precise details and finishes. Whether prototyping, small batch production, or creating complex parts, our expertise and equipment guarantee results that meet professional standards.

Cost savings

For businesses and individuals, using a 3D printing service can provide significant cost savings. Purchasing your own 3D printer, especially a model suitable for precision work or larger-scale production, can require a large investment. There are also costs associated with materials, maintenance, and any training to operate the printer. By using our service, customers can avoid these costs and pay only for the prints they actually need.

No 3D model but want something 3D printed?

We have a modern 3D scanner that can be used to scan most products. See: 3D Scan Service for more information.

Even if you don't have a property we can often do something for you. We have already helped many companies and individuals with the development of their project. These projects are very diverse, from the first phase to the final finished products we can help.

Some examples of our services.

- Scanning a part which then needs to be modified or improved

- Tools or components needed for process optimization or process improvement.

- Reproducing plastic parts that are no longer available.

- Printing prototypes & small production batches.

- Printing parts that cannot be produced by conventional manufacturing methods.

- Bridging long delivery times from your usual supplier who are often on another continent.

Sectors:

- Prototyping and Product Development: Fast and cost-effective prototyping and final product creation, ideal for companies looking to innovate.

- Architecture and Construction: Print detailed scale models and specific building components.

- Industry: Printing of machine parts, tools and production aids.

- Education and Research: Tangible models for educational purposes.

The service is suitable for anyone looking for customization, precision and innovation.

Printing methods

-

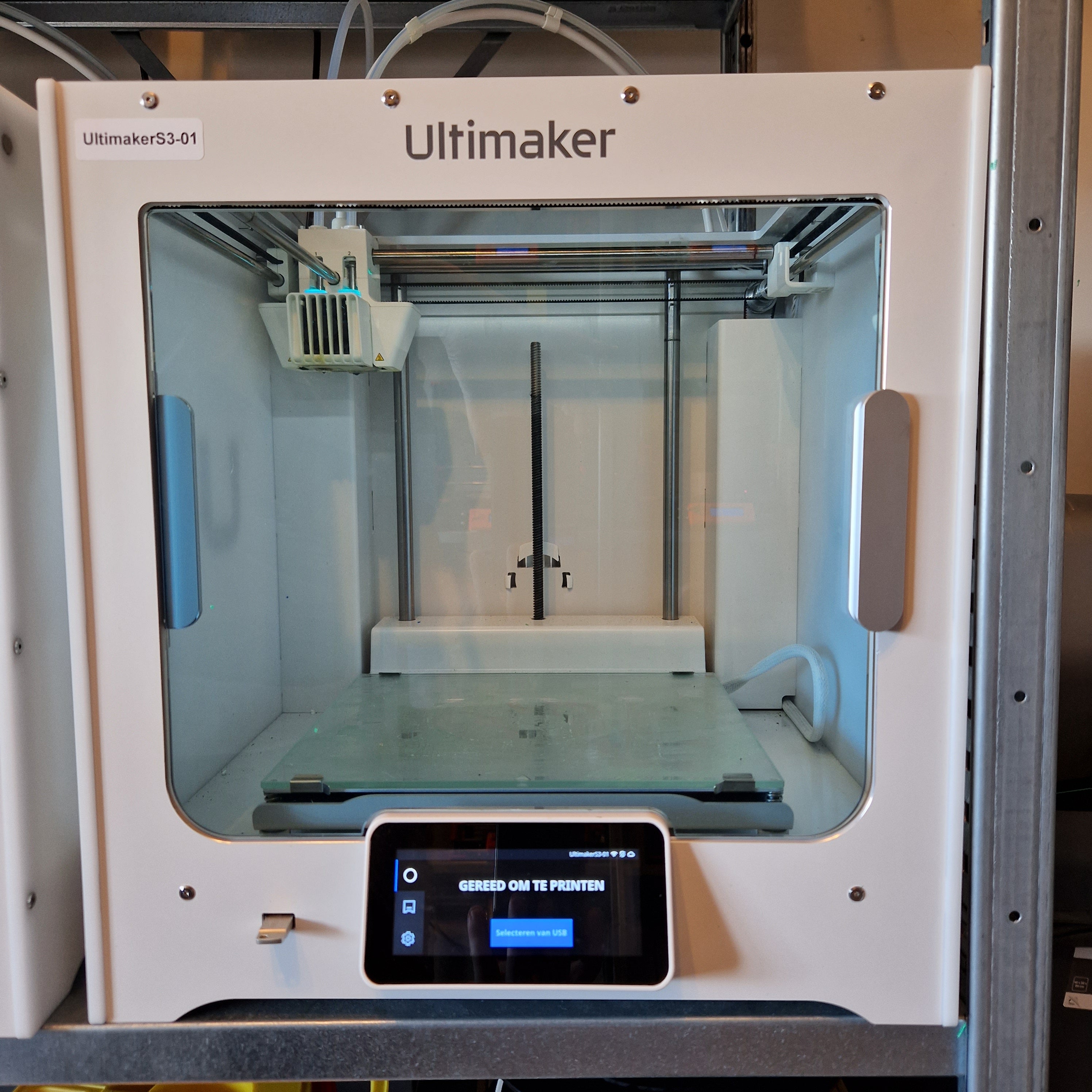

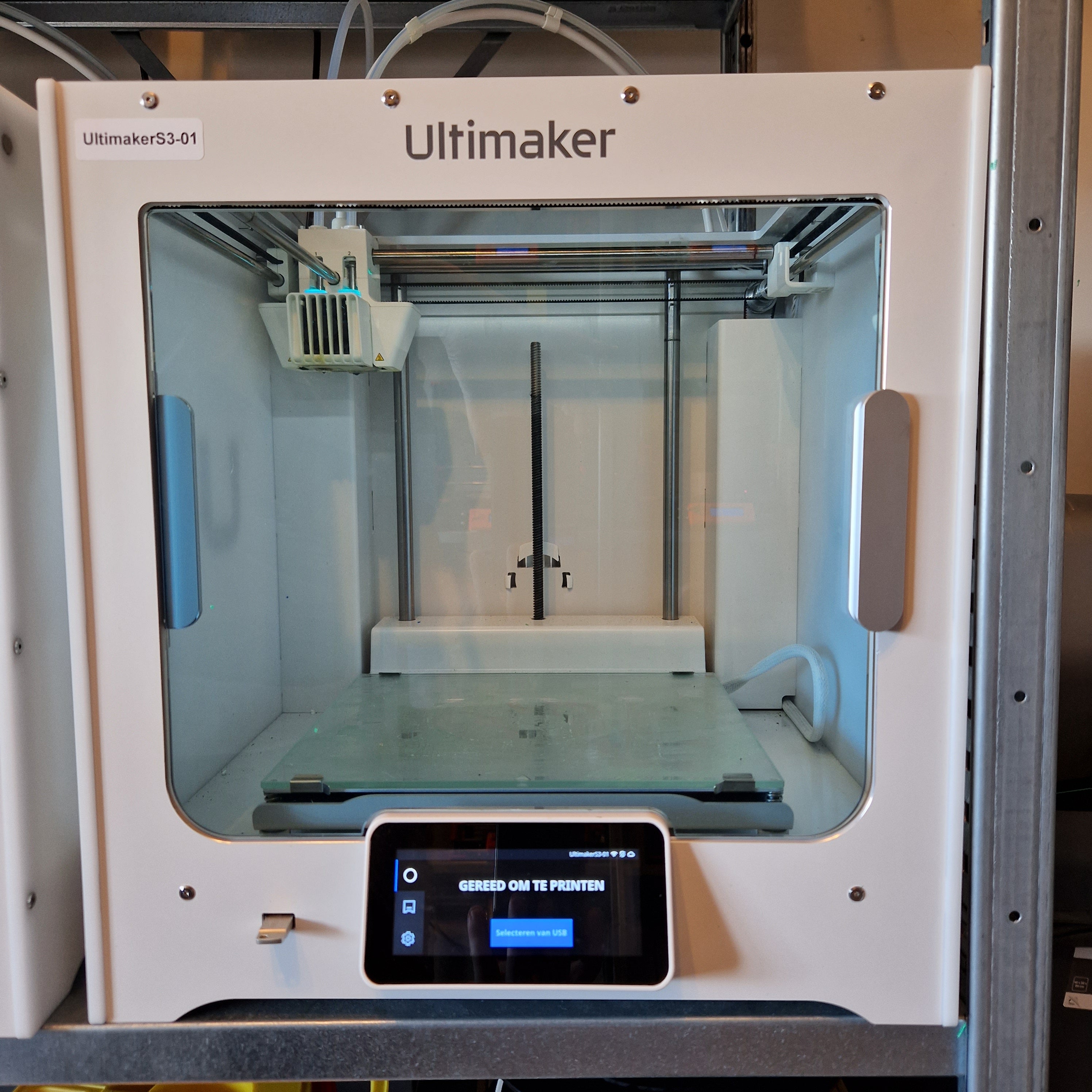

FDM (Fused Deposition Modeling)

FDM is a 3D printing technique in which a movable nozzle (extruder) layers a long, thin thread of thermoplastic material. By purposefully moving the extruder and/or platform, the desired shape is applied, layer by layer. As the liquid material solidifies after the application of each layer, the desired shape can thus be built up. In this way, a three-dimensional object is created layer by layer.

This technique is mainly used to quickly produce strong products, which are very close to injection molded products. -

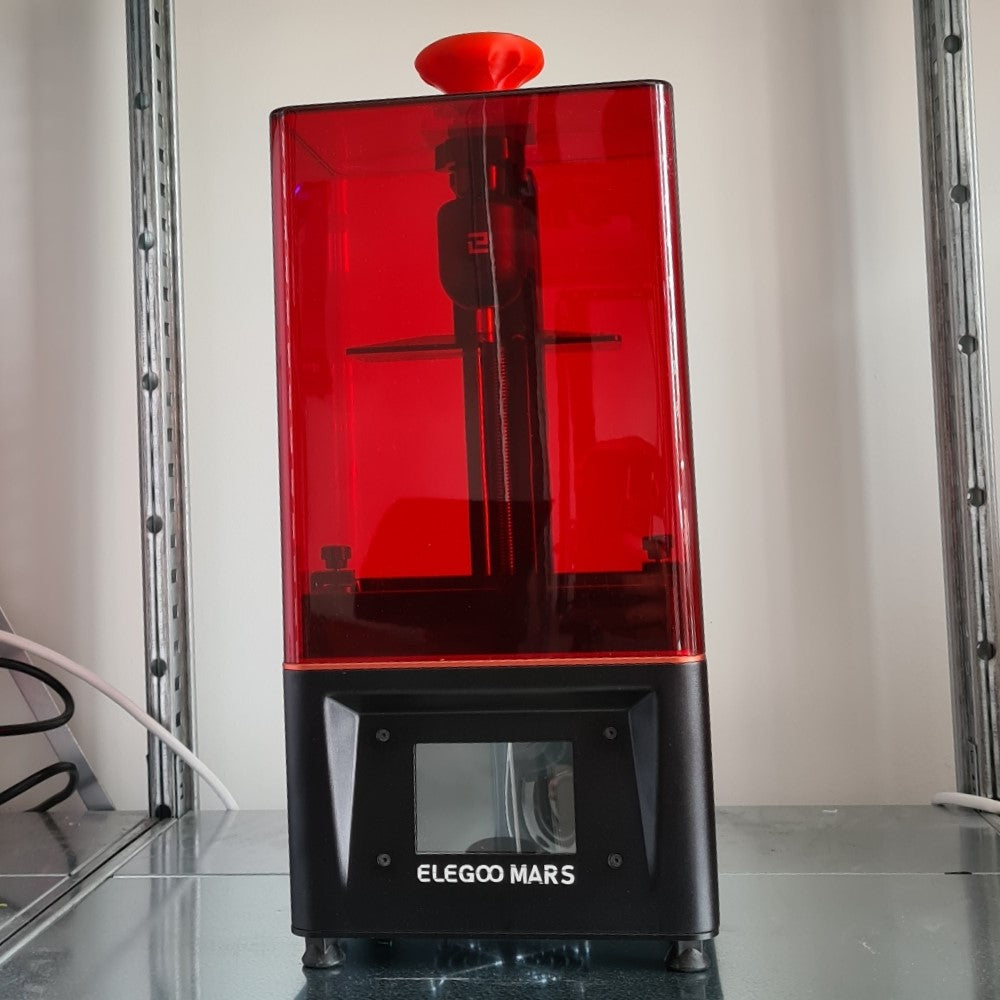

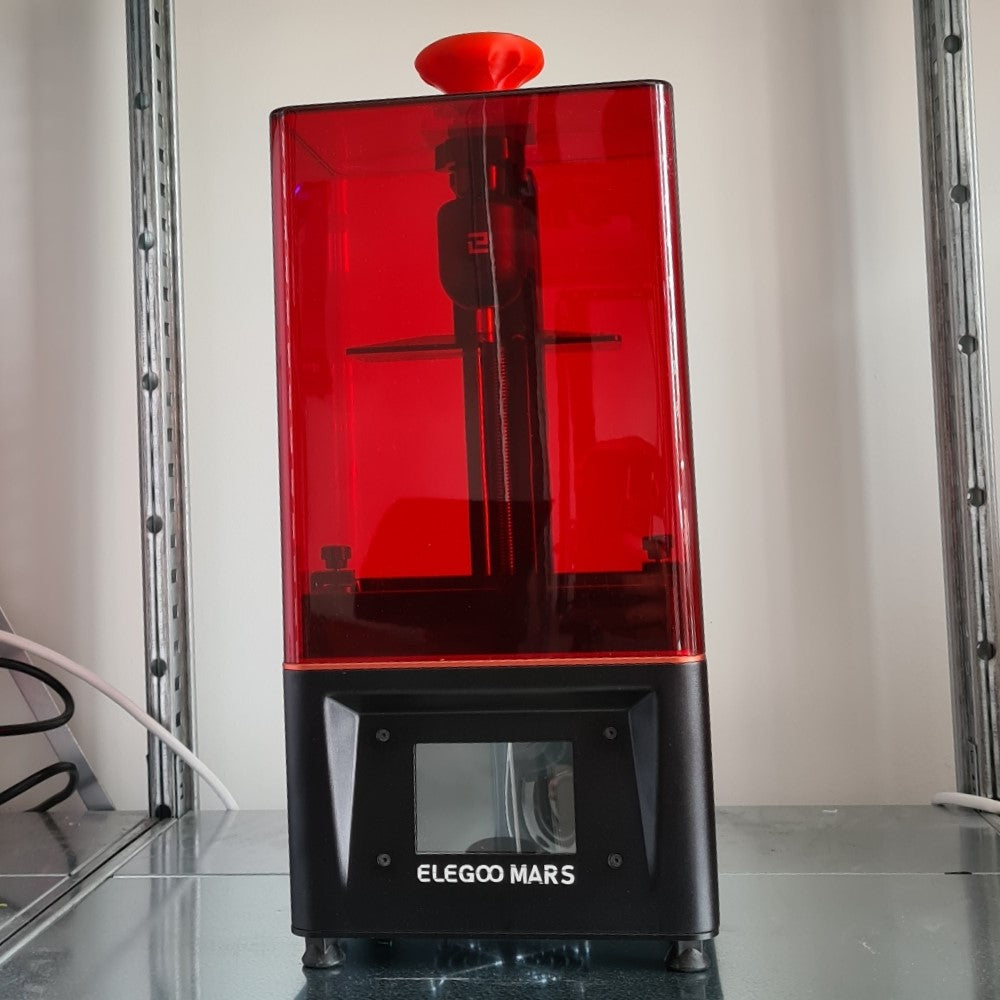

LCD (resin)

LCD is a 3D printing technique that uses light to project a complete cross-section of the product onto a container of liquid material (resin). This involves hardening one layer of material and lifting a layer thickness. Then the next layer is exposed and cured, building up the product layer by layer. This process involves working with very thin pillars, which support the overhanging parts of the model. These support pillars are easily removed after printing.

The advantage of this technique, compared to FDM, is that it allows printing in a higher resolution. This ensures high shape and dimensional accuracy and excellent surface quality, making this technique ideally suited for small and finely detailed parts.

Afmetingen

The only restriction we have for your 3D design is the size of the model. This is because it must fall within the dimensions of our printers. Note: This is about the size of one part. So if your design consists of multiple parts, it is possible that they will be printed with the maximum dimensions and then attached/glued together. Different printers are used for the two printing methods described above. This also includes different dimensions.

-

FDM printers

Our FDM printers can print models with the following maximum dimensions:

Width: 500 mm

Length: 500 mm

Height: 500 mm -

LCD (resin) printers

OurLCD(resin) printerscanprint models with the following maximum dimensions:

Width: 120 mm

Length: 68 mm

Height: 155 mm

Materials

You have a choice of materials with which to have your 3D design printed. Below are the materials we use, including key features.

PLA: This is the most common and most popular material today. With PLA it is possible to print very detailed objects. It is a biodegradable material mainly used for products that need to look good, but are not exposed to high temperatures or forces.

ABS: This is a plastic widely used for injection molding (for example, for the well-known LEGO blocks). ABS is characterized by its high melting point, strength and impact resistance. It is the most widely used filament for 3D printing after PLA for its good mechanical properties.

PETG: This is a combination of the properties of PLA and ABS. It is very user-friendly and strong. The difference is that it is more flexible and therefore slightly softer, making it more likely to scratch. In addition, it is a durable type of plastic that resists chemicals well.

ASA: This plastic is very strong, rigid and also has a high mechanical resistance. This ensures high UV and chemical resistance, making this material extremely suitable for outdoor use. In addition, ASA hardly ages and shrinks and does not develop a yellowish color when the material is exposed to the sun.

TPU: This is a plastic with high elasticity, which makes it perfect for products that need to be flexible. An additional advantage is that TPU is highly resistant to chemicals and it has good UV resistance. We have multiple hardnesses of TPU so we can choose the best hardness in consultation with you

Nylon: This is a very stable plastic with a very high surface quality. It is mainly used for finished products that need to be very strong. This material can withstand high temperatures and has a very low coefficient of friction.

Carbon Filled Nylon: This is a nylon which is filled with carbon fibers which gives a considerable amount of extra strength and stiffness to the nylon. The material does not lose strength up to 120ºC and is therefore ideally suited for a wide variety of parts. This material is widely used in the automotive industry.

File Types

In order to print your 3D design, we accept different types of files:

.STL files.

STEP files

.OBJ files

If you have one of these file types, you can share it with us and we can get started printing your design after a quick check.

Is your file format not listed here? Please contact us!

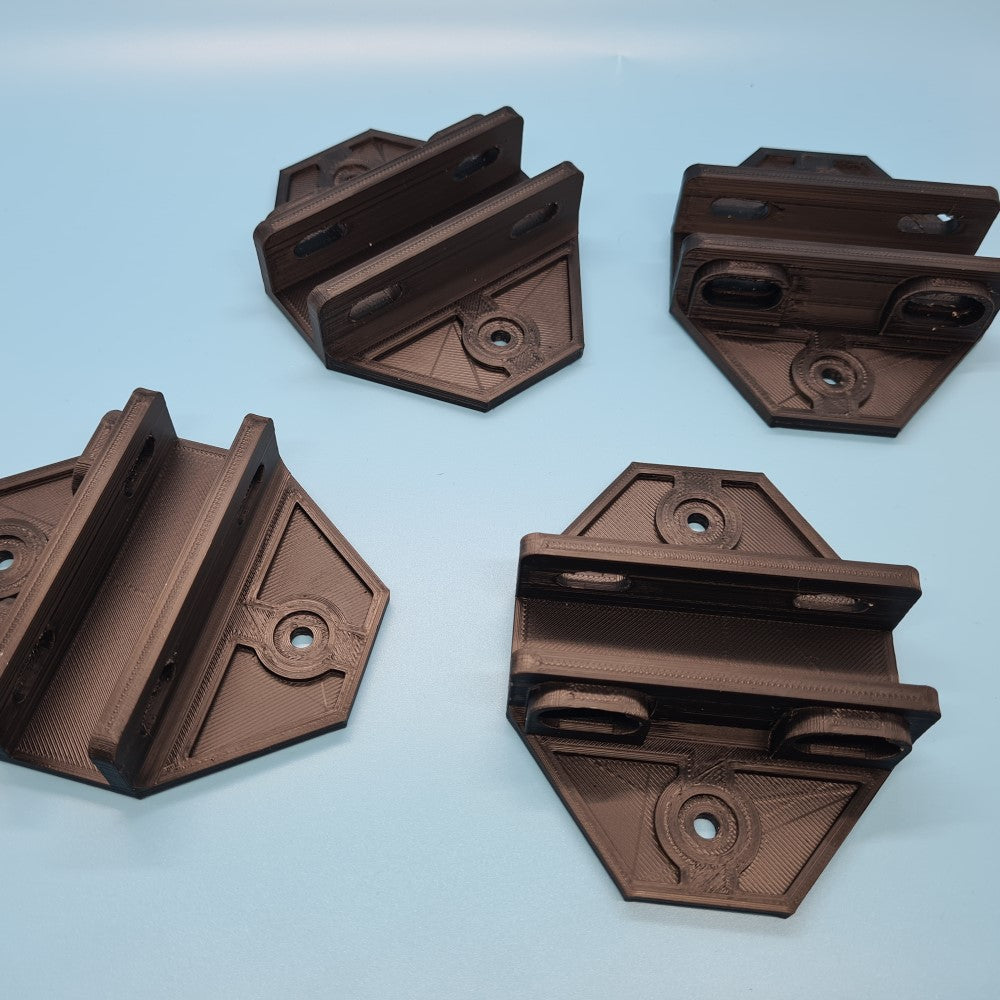

Various examples print service

-

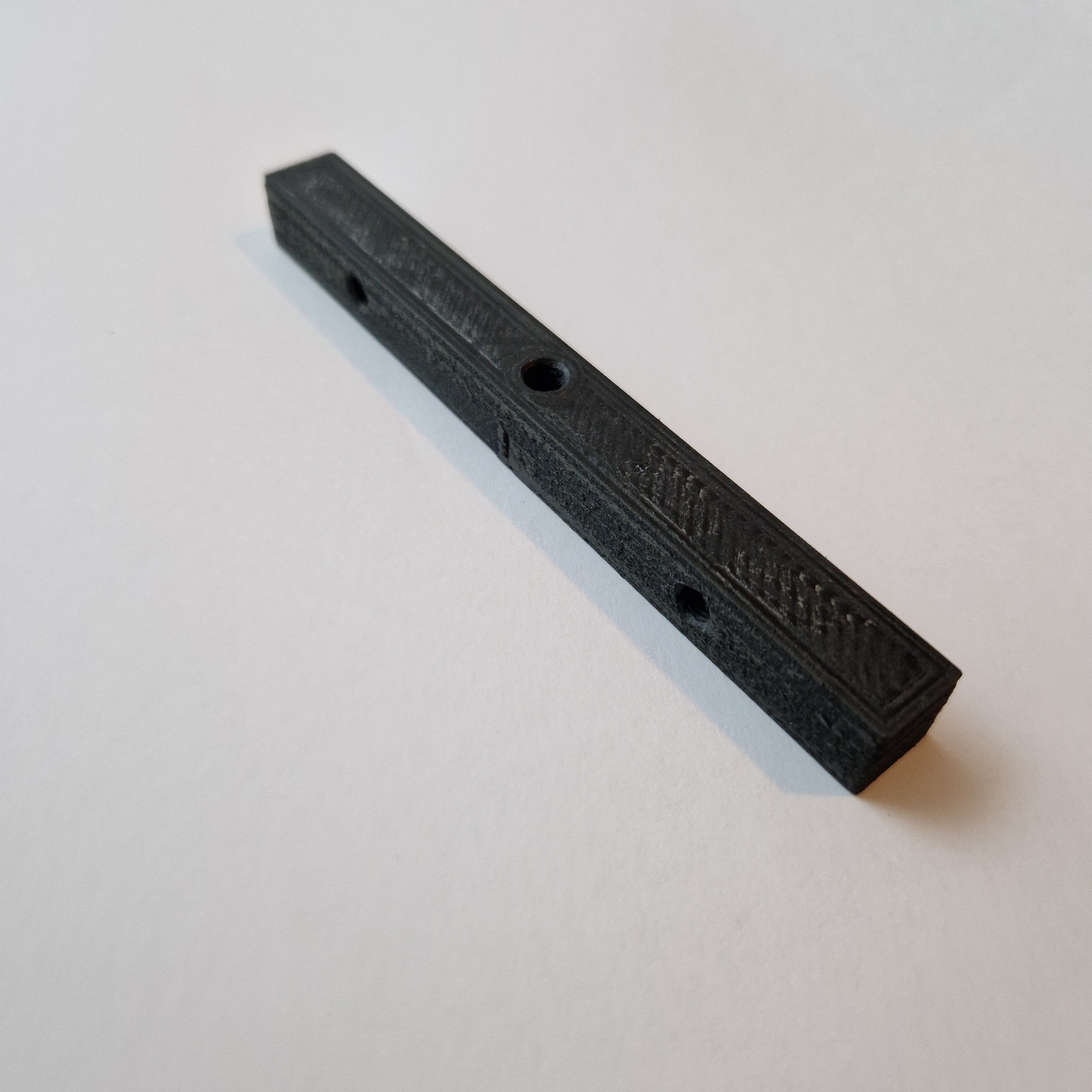

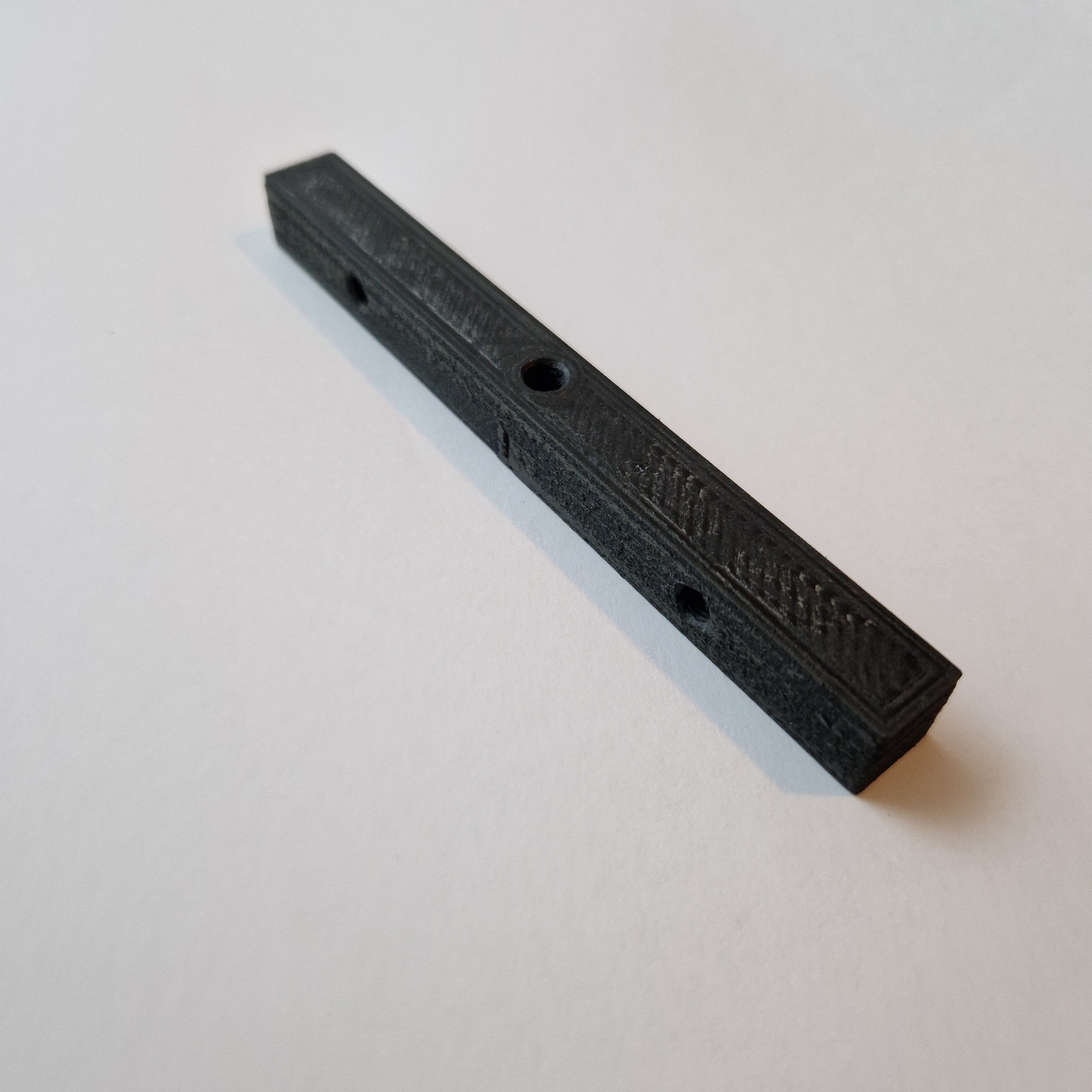

ABS (FDM)

-

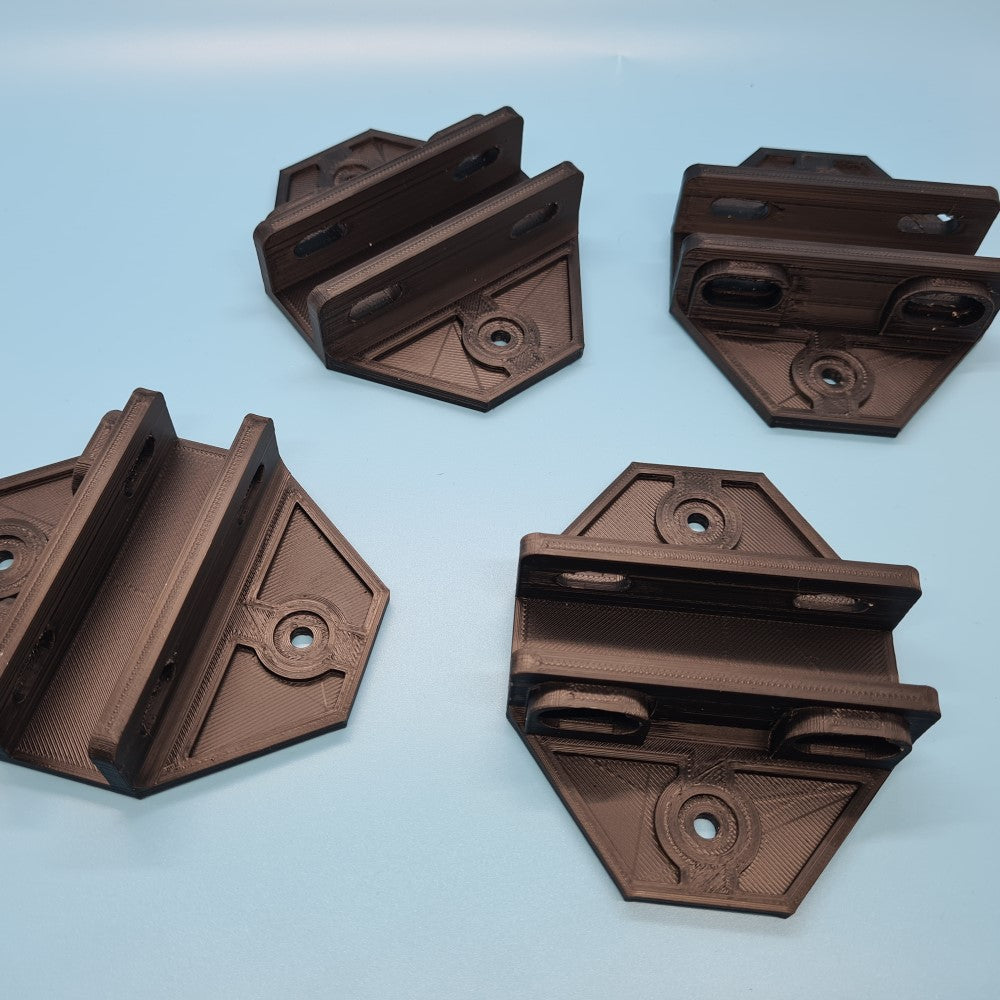

PETG (FDM)

-

PA CF (FDM)

-

PLA (FDM)